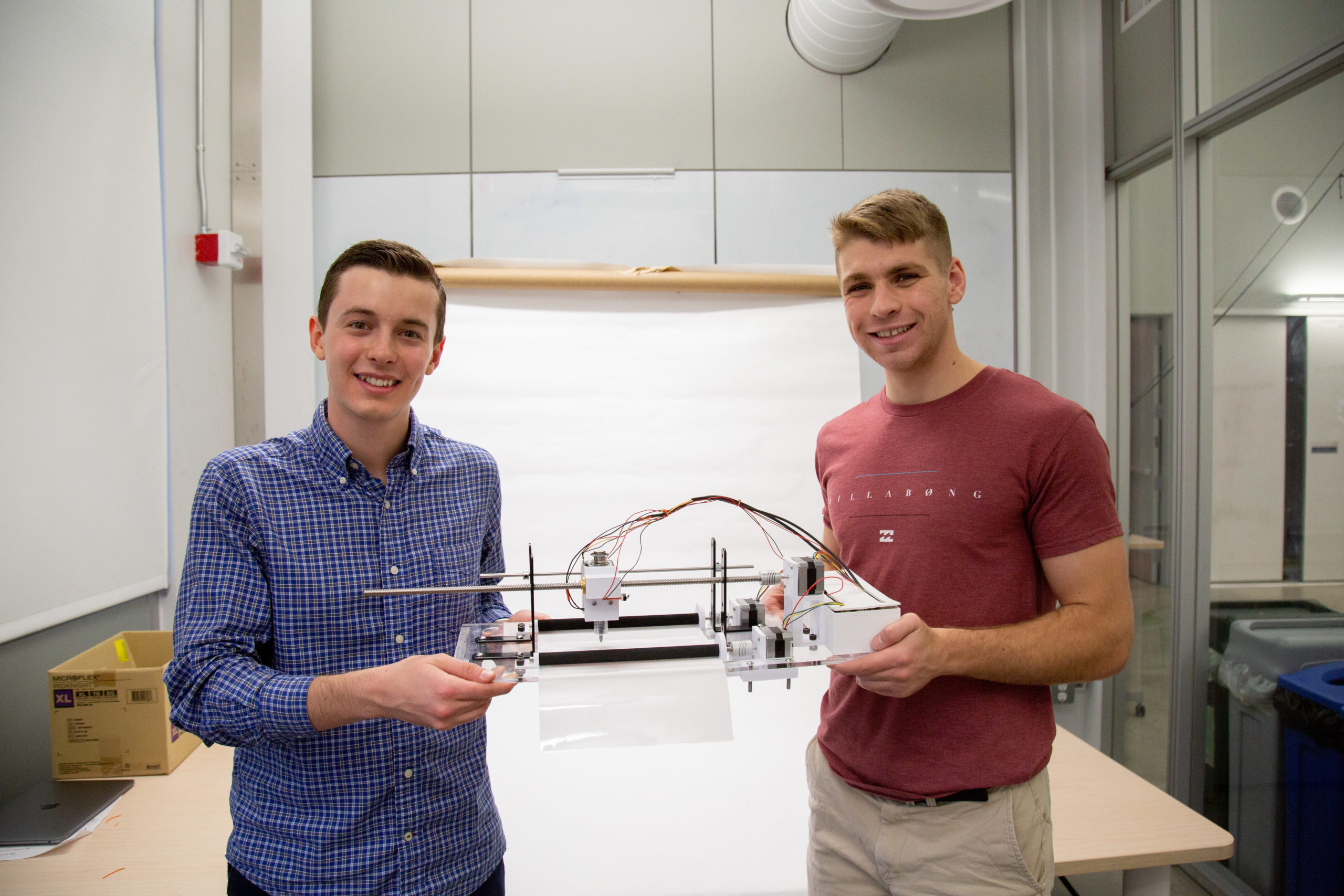

Team: Andrew Ansell, Matthew Drake, Tony Kim, Joshua Ott.

Course: Mechatronics Design, Fall 2019

Research has found that braille literacy increases professional opportunities for people with visual impairments and blindness, however, most braille printers on the market are unaffordably priced, making braille printing inaccessible to many. b.Print is a low-cost desktop braille printer with the same functionalities as existing printers, but at a more accessible and affordable price.

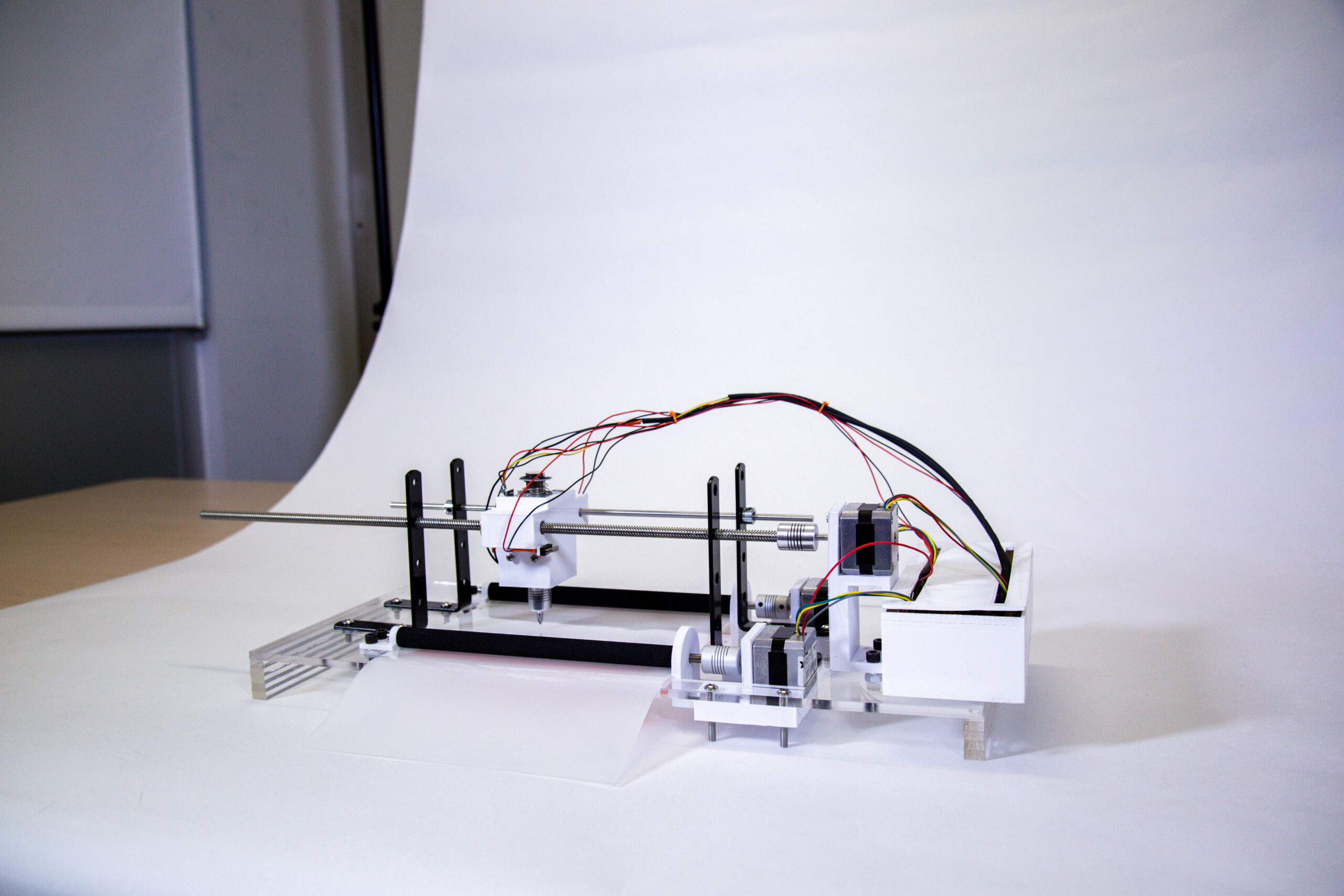

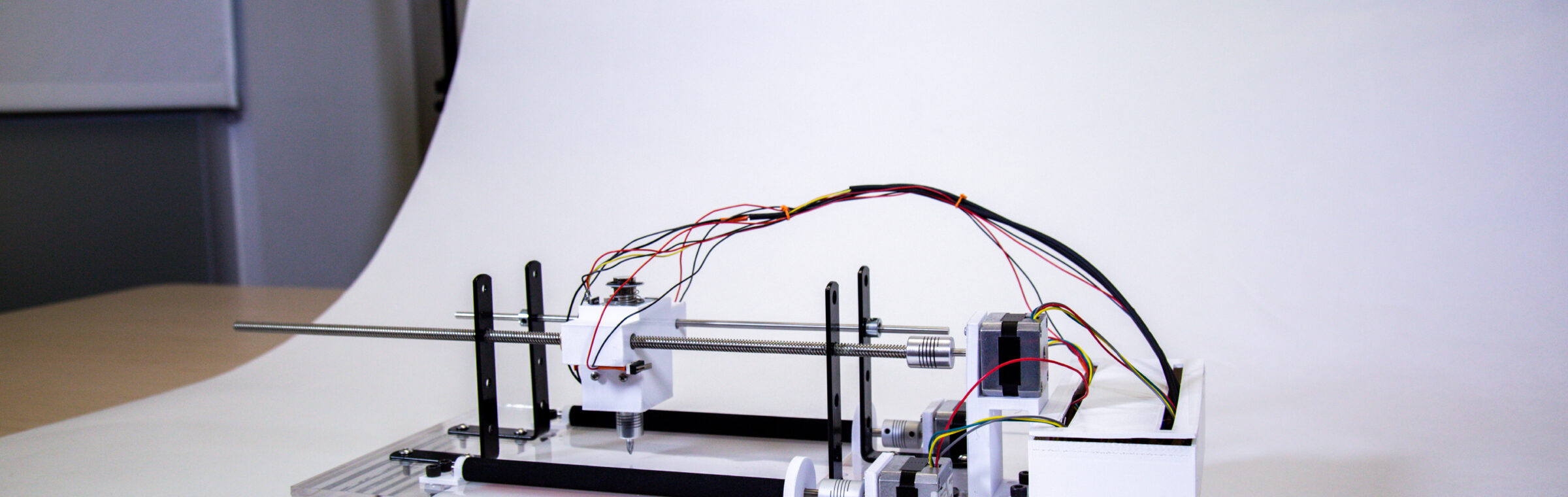

The project consists of 3D-printed carriages and holders, printer paper rollers, a base plate with a printing slot, a solenoid, and 3 stepper motors. The solenoid setup moves via a power screw to achieve precise movements, supported by a 3D-printed box designed to hold the solenoid at the exact height needed. The roller system will grab on to the paper on 2 lines of contact, granting full control of the paper. The power screw and the roller system are powered by stepper motors, ensuring the accuracy of all moving parts. The majority of non-electric parts are 3D-printed, which allows for the files to be open-sourced online. Any individual, in this case, a family member or friend of the end-user, would simply need access to a 3D printer and a hardware store in order to assemble their printer.

Printing is initialized when the user inputs a phrase into the Arduino integrated developer environment (IDE). From there, the software converts text to a large matrix of 1’s (dots) and 0’s (blank spaces). These commands are sent to a Teensy 3.2 microcontroller, which controls a solenoid carriage in the x-direction, using a stepper motor driving a power screw. Each time the solenoid reaches a 1 in the matrix, it punches down with 10N of force. Once one line of dots has been punched, two supporting stepper motors rotate 90 degrees to drive the sheet forward one line. This continues until a full page is printed.